Set Target Pressure

Input customer’s preferred testing parameters.

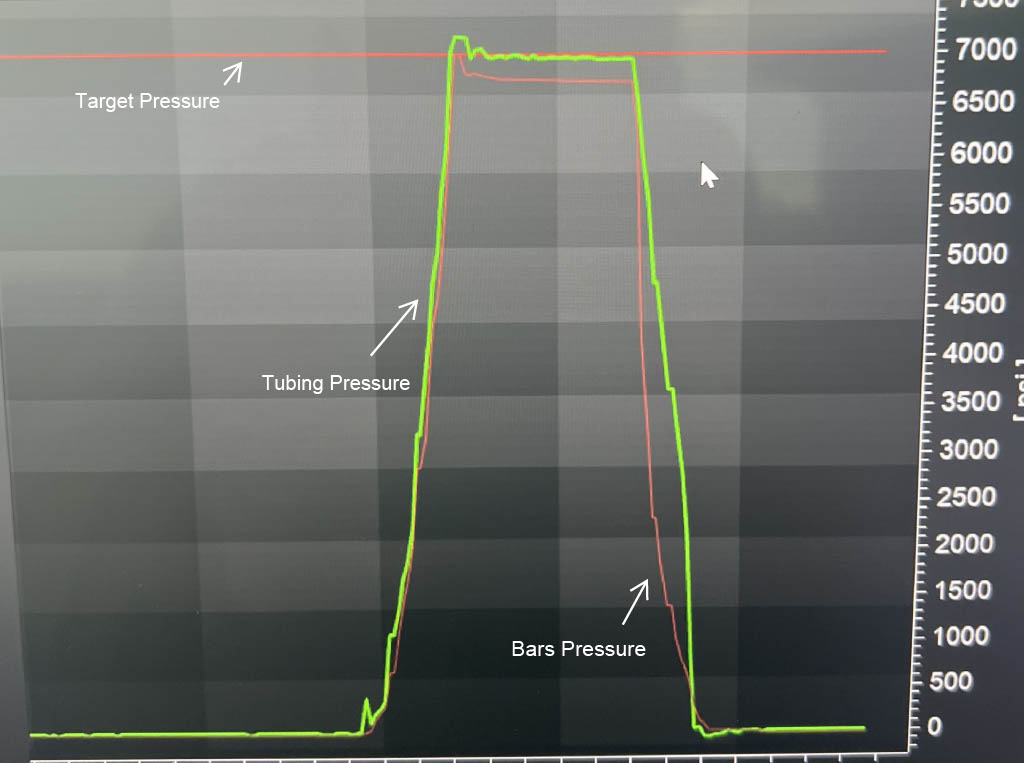

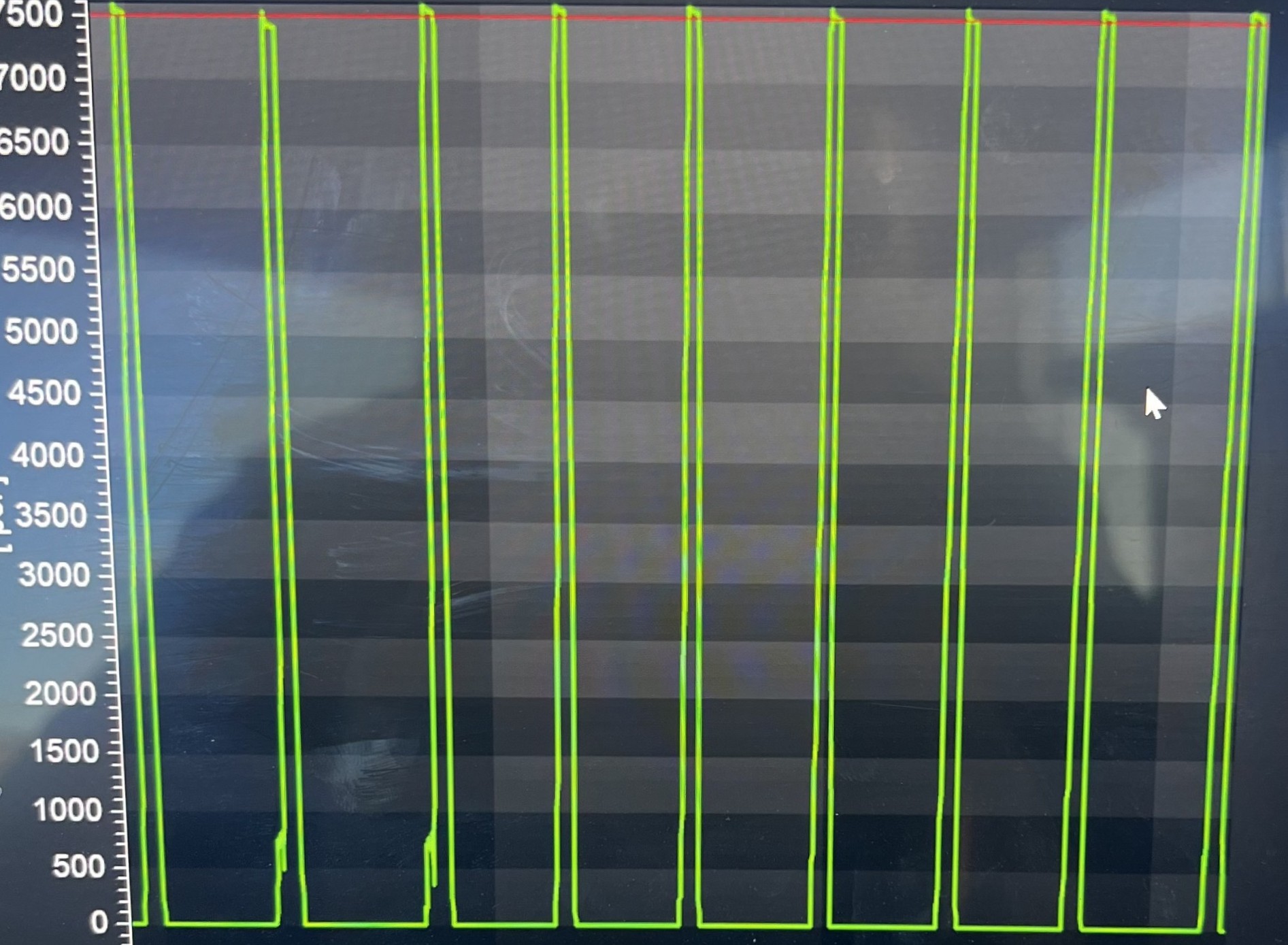

ATS combines automated hydrotesting with patented technology that delivers the same trusted results — every job, every day, no exceptions. Our automated control system maintains test pressure between 98.6% and 100% of target, eliminating human variance and proving what true precision looks like. Manual gauges drift and rely on operator interpretation. Results vary from one operator to the next — because ‘close enough’ shouldn’t be accepted in hydrotesting. The ATS system removes that uncertainty entirely — every test is recorded, verified, and repeatable, because guessing isn’t testing.

Input customer’s preferred testing parameters.

Allow the system to verify all components function properly.

Sit back — accuracy’s driving today.

When pressure testing, every second counts — and so does every glance.

If your eyes are locked on a gauge, they’re not on the crew. And on the rig floor, that’s where the real danger lies.

Pressure failures happen fast. A loose fitting, a weakened hose, fatigued metal — it only takes a split second for stored energy to release. And when it does, no one watching a gauge can react quickly enough to protect the team.

That’s why we let the automated test truck handle the numbers. It controls the pressure, monitors every reading, and logs each result — giving the tester freedom to focus on what truly matters: keeping the crew safe from unexpected pressure releases.

Instead of dividing attention between a dial and the rig floor, operators can stay alert, watch the floor, read the body language, and keep the crew out of danger.

Automation doesn’t just make testing more consistent — it makes it safer.

Because the most important thing to monitor isn’t the pressure...

It’s your people.

It only takes a split second for an unexpected pressure release — and looking up comes too late

We test those same split seconds — with precision, proof, and safety guaranteed.

A pressure test doesn’t take long — seven seconds, maybe thirty — but those seconds decide everything. You wouldn’t close your eyes driving down the interstate, not when lives are on the line. Yet every time someone stares at a gauge instead of the rig floor, that’s exactly what happens. Pressure doesn’t wait. It fails fast. And when it does, no one watching a dial will ever react in time.

So before you call a competitor, ask yourself — are you willing to risk a crew member’s safety for a few seconds of testing? Are you betting they’ll catch every collar leak and deliver proof you can trust? At ATS, every test is controlled to your company’s exact specifications, logged with precision, and backed by tamper‑proof data. Because when it comes to safety, there’s no second chance — and no substitute for proof.

Our automation isn’t a replacement — it’s an evolution. From the ground up, ATS systems were engineered with automation and manual control working in perfect tandem — designed together, not added later. Every valve, sensor, and safety circuit can operate manually with the same precision, data integrity, and safety verification as automation.

Most test trucks on location share the same few parts, the same two major manufacturers, and the same story — reliability issues, constant repairs, and control systems that never feel quite right. Efficiency and accuracy depend on who’s in the driver’s seat. ATS built something different. We engineered our systems to stay online, perform when others can’t, and keep crews working instead of waiting on another truck to replace the one that broke down. Because ATS wasn’t built to rely on one mode — it was built so the work never stops, and it continues to evolve every day — unlike the outdated testing methods still used across the industry.

Our automation doesn’t replace the operator — it empowers them. Every ATS unit is built with a complete manual control system that mirrors all automated functions — pressure logging, calibration, and safety verification. If automation ever pauses, testing continues seamlessly — because ATS keeps the job moving, not waiting. You stay in control — always.